Air Shower Manufacturers in Chennai

In Chennai, a city known for its rapid industrialization and commercial expansion, maintaining stringent cleanliness and contamination control has become increasingly important.

As industries across the city strive for excellence, they face the challenge of ensuring that their environments meet the highest standards of hygiene. This is especially true for sectors such as pharmaceuticals, electronics, biotechnology, and food processing, where even minute levels of contamination can have significant impacts on product quality and safety.

Among the many air shower manufacturers in Chennai, Cronax Industries stands out as a leader in this field. With a reputation for innovation and quality, Cronax Industries has become a trusted name for businesses seeking reliable and effective contamination control solutions.

Their air showers are designed to address the specific needs of Chennai’s diverse industrial landscape, providing tailored solutions that enhance cleanliness and operational efficiency.

Whether it’s the need for high-performance air showers to support pharmaceutical research, electronics manufacturing, or food safety, Cronax Industries offers products that meet the rigorous demands of various sectors. Their commitment to quality, customization, and local expertise ensures that businesses in Chennai receive solutions that not only meet but exceed industry standards.

As Chennai continues to grow and evolve, the role of effective contamination control becomes even more critical. Cronax Industries is at the forefront of this industry, delivering advanced air shower systems that help businesses maintain cleanliness, comply with regulations, and achieve operational excellence.

What Is An Air Shower?

Air showers are specialized enclosed chambers typically used in cleanroom environments or controlled environments. They serve as a critical contamination control measure, preventing particles from entering a clean area. Here’s a brief overview:

Air showers use high-velocity, HEPA-filtered air jets to remove dust, particles, and other contaminants from personnel or equipment before they enter a cleanroom.

These chambers are usually designed with interlocking doors to ensure that both doors are not open at the same time, maintaining the cleanroom’s integrity.

When a person or object enters the air shower, the doors lock, and a series of air jets are activated. The high-speed air jets dislodge and blow off contaminants, which are then captured by the air shower’s filtration system.

Commonly used in industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, and food processing, where maintaining a contaminant-free environment is critical.

Importance of Air Showers in Cleanrooms

Air showers are critical in maintaining the integrity of cleanrooms by ensuring that contaminants are minimized. An air shower system clean room setup ensures that the highest levels of cleanliness are maintained, which is crucial for industries such as pharmaceuticals, biotechnology, and semiconductor manufacturing.

The Working of An Air Shower

The working of an air shower involves several steps to effectively remove contaminants from personnel or equipment before they enter a cleanroom or controlled environment. Here’s a detailed explanation of how an air shower chamber works:

1. Entry and Activation:

- Access: The person or object enters the air shower through an entry door, which is usually interlocked with the exit door to prevent both from being open simultaneously.

- Detection: Sensors detect the presence of the person or object, automatically activating the air shower cycle.

2. High-Velocity Air Jets:

- Air Jets Activation: High-velocity jets of HEPA-filtered air are directed at the person or object from multiple nozzles positioned inside the chamber.

- Airflow: The air jets create a turbulent flow that dislodges and blows off particulate matter, dust, and other contaminants from the surfaces.

3. Contaminant Removal:

- Filtration System: The dislodged contaminants are captured by the air shower’s filtration system. The air is recirculated through HEPA (High-Efficiency Particulate Air) filters that remove 99.97% of particles as small as 0.3 microns.

- Air Circulation: Clean, filtered air is continuously circulated within the chamber to maintain an effective cleaning process.

4. Cycle Completion:

- Cycle Duration: The air shower cycle typically lasts between 20 to 60 seconds, depending on the design and requirements of the cleanroom.

- Deactivation: Once the cycle is complete, the air jets stop, and the exit door unlocks.

5. Exit and Access to Cleanroom:

- Exiting: The person or object exits the air shower booth through the exit door, now free of contaminants.

- Entry to Cleanroom: They can now enter the cleanroom or controlled environment with significantly reduced risk of introducing contaminants.

Key Components of an Air Shower:

- Interlocking Doors: Prevent both entry and exit doors from being open at the same time to maintain cleanroom integrity.

- HEPA Filters: Capture and remove particulate contaminants from the air.

- High-Velocity Air Nozzles: Direct jets of clean air to dislodge contaminants.

- Control System: Manages the operation of the air shower, including timing, air jet activation, and door interlocking.

Why Choose Cronax Industries ?

Cronax Industries is the top choice for air shower manufacturing in Chennai due to their cutting-edge technology, customized solutions, and superior quality. With local expertise, comprehensive support, and competitive pricing, they offer reliable and efficient systems tailored to meet regional needs. Their commitment to regulatory compliance and sustainability further underscores their excellence in providing high-performance air showers.

Contact Us

Chennai’s Largest Air Showers Original Equipment Manufacturer (OEM)

1. Construction and Design:

- Material: Stainless steel (304/316), powder-coated steel, or other durable materials.

- Dimensions:

- External: (customizable based on requirements)

- Internal: (customizable based on requirements)

- Doors:

- Type: Interlocking, manual, or automatic sliding/swing doors.

- Material: Stainless steel, tempered glass.

- Operation: Pneumatic or electric control.

2. Airflow and Filtration:

- Air Velocity: 20-25 m/s (meters per second) at nozzle exit.

- Airflow Volume:

- Supply: 1000-2000 CFM (cubic feet per minute) depending on size and model.

- Exhaust: Matching supply volume to ensure balanced pressure.

- Filtration:

- Pre-filters: G4 (EN779) or MERV 10-13.

- HEPA filters: H13/H14 (EN1822) or equivalent, with 99.97% efficiency at 0.3 microns.

3. Air Shower Room Cycle:

- Cycle Time: Adjustable, typically 15-60 seconds.

- Air Jets:

- Number: 10-30 adjustable nozzles (varies based on model and size).

- Configuration: Multi-directional, strategically placed for optimal coverage.

- Noise Level: Below 70 dB(A).

4. Control System:

- User Interface: Touchscreen control panel or PLC-based system.

- Control Features:

- Cycle start/stop.

- Adjustable cycle time.

- Door interlock status.

- Filter status indicators.

- Interlock System: Ensures one door remains closed while the other is open to maintain cleanroom integrity.

5. Electrical and Power:

- Power Supply: 220-240V, 50/60 Hz, single-phase or three-phase.

- Power Consumption: 1-2 kW (varies based on model and features).

- Emergency Stop: Accessible emergency stop button.

6. Safety Features:

- Emergency Interlock Release: Allows manual override of door interlock in case of emergency.

- Alarm System: Visual and audible alarms for system faults, door status, and emergency conditions.

- Door Sensors: Proximity or magnetic sensors to detect door status.

7. Compliance and Standards:

- Cleanroom Standards: ISO 14644-1, ISO 14698.

- Electrical Safety: CE, UL, or equivalent certifications.

- Air Quality Standards: Compliance with industry-specific air cleanliness standards.

8. Optional Features:

- UV-C Sterilization: For additional microbial decontamination.

- Ionization System: For enhanced particle removal.

- Custom Size and Design: Tailored to specific application needs.

- Remote Monitoring and Control: Integration with building management systems (BMS).

Chennai’s Largest Air Shower Original Equipment Manufacturer (OEM)

Benefits of Air Showers in Chennai

Air showers offer numerous advantages for businesses and industries in Chennai, addressing both local environmental challenges and specific operational needs. Here’s how air showers can benefit various sectors in Chennai:

Enhanced Contamination Control In Chennai’s bustling industrial and commercial environment, dust and particulate matter are prevalent due to rapid urbanization and construction activities. Air showers efficiently remove these contaminants from personnel and equipment, ensuring that cleanroom and controlled environments remain free from potential sources of contamination.

Improved Cleanliness Standards For industries such as pharmaceuticals, electronics, and food processing, maintaining high cleanliness standards is crucial. Air showers help achieve this by ensuring that any personnel or equipment entering sensitive areas are free from dust and other particles, supporting the integrity and quality of products and processes.

Compliance with Regulatory Standards Chennai’s industries, especially those in the pharmaceutical and biotechnology sectors, must adhere to stringent cleanliness and safety regulations. Air showers assist in meeting these regulatory requirements by providing an effective solution for contamination control, helping businesses comply with industry standards and avoid regulatory issues.

Reduction in Downtime and Contamination-Related Costs By preventing contamination before it enters critical areas, air showers help minimize the risk of costly downtime and disruptions. This leads to reduced maintenance and cleaning costs, as well as fewer product recalls or rework due to contamination issues.

Energy Efficiency Modern air showers are designed to be energy-efficient, which aligns with Chennai’s growing focus on sustainability. Advanced systems use technology that minimizes power consumption while delivering effective performance, helping businesses reduce their energy costs and environmental footprint.

Customization for Diverse Applications Chennai’s industrial landscape is diverse, with varying needs across sectors such as electronics, textiles, and healthcare. Air showers can be customized to suit different applications, ensuring that each system is tailored to meet the specific requirements of various industries and facility layouts.

Enhanced Worker Safety and Comfort By removing contaminants from clothing and personal protective equipment, air showers contribute to a safer and more comfortable working environment. This is particularly important in industries where worker safety and hygiene are paramount.

Versatility in Design Air showers come in various configurations, including single-person, multi-person, and tunnel designs, making them versatile enough to fit different facility sizes and requirements. This adaptability is beneficial for businesses with specific layout or operational needs.

Enhanced Productivity By ensuring that only clean personnel and equipment enter sensitive areas, air showers help maintain smooth operations and high productivity levels. This is crucial for maintaining efficient workflows and achieving business goals in Chennai’s competitive market.

Cronax Industries: Chennai’s Largest Air Shower Original Equipment Manufacturer (OEM)

Applications of Air Showers in Chennai

In Chennai, where rapid industrial growth and urban development present unique environmental challenges, air showers prove to be a valuable asset for various sectors. Here’s how air showers can be effectively applied across different industries in Chennai:

Pharmaceutical Industry

- Application: Ensuring that personnel and equipment entering cleanrooms or production areas are free from contaminants.

- Benefit: Maintains the highest levels of hygiene and compliance with stringent regulatory standards, crucial for drug safety and efficacy.

Electronics Manufacturing

- Application: Removing dust and particulate matter from components and workers before they enter sensitive assembly areas.

- Benefit: Prevents contamination that can lead to defective products or reduced performance, ensuring high-quality electronics.

Biotechnology Labs

- Application: Decontaminating lab coats and equipment before entering research or production areas.

- Benefit: Protects sensitive experiments and maintains the integrity of biological research, contributing to accurate and reliable results.

Food Processing

- Application: Ensuring that workers and tools are free from contaminants before entering food processing areas.

- Benefit: Enhances food safety and hygiene, preventing contamination that could affect product quality and consumer health.

Textile Industry

- Application: Removing dust and fibers from clothing and equipment before they enter clean or specialized production areas.

- Benefit: Maintains the quality of textile products by preventing contamination from dust and other particulates.

Healthcare Facilities

- Application: Decontaminating staff and equipment before entering sterile environments such as operating rooms or patient care areas.

- Benefit: Reduces the risk of infections and supports overall cleanliness in healthcare settings, crucial for patient safety.

Aerospace and Defense

- Application: Removing contaminants from components and personnel before they enter high-precision assembly or maintenance areas.

- Benefit: Ensures the reliability and performance of aerospace and defense systems by preventing contamination that could affect critical components.

Laboratories and Research Facilities

- Application: Decontaminating research tools and personnel before entering experimental areas.

- Benefit: Preserves the purity of experiments and research environments, contributing to accurate and valid research outcomes.

Cleanrooms in Electronics and Semiconductor Industries

- Application: Providing pre-entry decontamination for personnel and equipment to maintain ultra-clean environments.

- Benefit: Supports the production of high-tech electronic components and semiconductors by preventing contamination that could impact performance and reliability.

Automotive Manufacturing

- Application: Removing dust and debris from automotive parts and assembly personnel before entering clean or specialized assembly areas.

- Benefit: Ensures high standards of cleanliness in automotive production, which is critical for maintaining quality and performance standards.

Cosmetics and Personal Care

- Application: Decontaminating personnel and equipment before they enter manufacturing areas where cosmetics and personal care products are produced.

- Benefit: Ensures product safety and quality by preventing contamination that could affect the final product.

Cronax Industries: Chennai's Largest Air Shower Original Equipment Manufacturer (OEM)

Cronax Air Showers,featuring HEPA filtration, adjustable air velocity, customizable sizes, with a 3-year warranty.

1. What is an air shower?

An air shower is an enclosed chamber that uses high-velocity, HEPA-filtered air jets to remove dust, particles, and other contaminants from personnel or equipment before they enter a cleanroom or controlled environment.

2. How does an air shower work?

An air shower works by directing high-velocity air jets at the person or object entering the chamber. These air jets dislodge and blow off contaminants, which are then captured by the chamber’s filtration system. The air is recirculated through HEPA filters to ensure only clean air is used.

3. Why do I need an air shower? Air showers are essential for maintaining contamination control in cleanrooms and other controlled environments. They help prevent contaminants from entering critical areas, thereby ensuring product quality, safety, and compliance with regulatory standards.

4. Where are air showers typically used?

Air showers are commonly used in industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, food processing, aerospace, defense, healthcare, laboratories, and more. Industrial air showers ensure contamination control by decontaminating personnel and equipment entering sensitive environments like manufacturing facilities.

5. How much space is required to install an air shower?

The space required depends on the size and design of the air shower. Air showers come in various sizes, so it’s important to measure the available space and consult with the manufacturer to determine the appropriate model for your needs.

6. How long does an air shower cycle take?

The duration of an air shower cycle is typically adjustable, ranging from 15 to 60 seconds. The exact time can be set based on the specific requirements of your application.

7. Can the air shower be customized to fit our needs?

Yes, air showers can be customized in terms of size, material, and features to meet the specific requirements of your facility and application.

8. What kind of maintenance is required for an air shower?

Regular maintenance includes cleaning or replacing pre-filters and HEPA filters, checking the operation of air jets, and ensuring that the control systems and door interlocks are functioning correctly. It’s recommended to follow the manufacturer’s maintenance guidelines.

9. How noisy is an air shower?

The noise level of an air shower is generally below 70 dB(A), which is comparable to the sound of a normal conversation.

10. What power supply is needed for an air shower?

Air showers typically require a power supply of 220-240V, 50/60 Hz, single-phase or three-phase, depending on the model.

11. What safety features are included in an air shower?

Safety features of air showers include interlocking doors to prevent both doors from being open simultaneously, emergency stop buttons, visual and audible alarms for system faults, and emergency interlock release mechanisms.

12. Are there different types of air showers?

Air showers come in various configurations, including single-person, multiple-person, tunnel, and equipment-specific designs, to suit different applications and facility layouts.

13. What is the cost of an air shower?

The cost of an air shower varies based on the size, features, and customization options. It’s best to request a quote from the manufacturer based on your specific needs.

14. How can I determine the right air shower for my facility?

To determine the right air shower, consider factors such as the size of the area, the number of personnel or amount of equipment needing decontamination, and specific cleanliness standards. Consulting with a manufacturer or cleanroom expert can help you choose the best option.

15. Top Air Shower Manufacturers in Chennai?

There are several air shower manufacturers around the world who provide customized solutions to meet specific industry needs. Cronax Industires is one of the best air shower manufacturers in Chennai offering a range of products tailored to local requirements and compliance standards.

16. What factors affect the air shower clean room price?

The price of an air shower for a clean room can vary based on several factors, including the size and configuration of the unit, the type of filtration system used (such as HEPA or ULPA filters), additional features like interlocking doors or programmable controls, and the materials used in construction (stainless steel, powder-coated steel, etc.). Customization options, installation costs, and the manufacturer’s brand and reputation also play a significant role in determining the overall cost.

17. Air Shower Price at Cronax Industries?

At Cronax Industries, air shower prices are determined based on several factors, particularly the customization of the product to meet specific customer requirements. Customization options such as size, material, filtration system (HEPA or ULPA), additional features (such as interlocking doors or programmable controls), and installation requirements all influence the final pricing. Buy air shower today with Cronax Industries.

18. What is a Pass Box air shower?

A pass box air shower typically refers to a specialized unit that combines the features of both a pass box and an air shower. It serves as a transfer chamber where materials or items can be passed between two environments (such as a clean room and an external area) while decontaminating through an air shower process.

For a comprehensive understanding of our Air Shower's technical specifications, please download our catalogue.

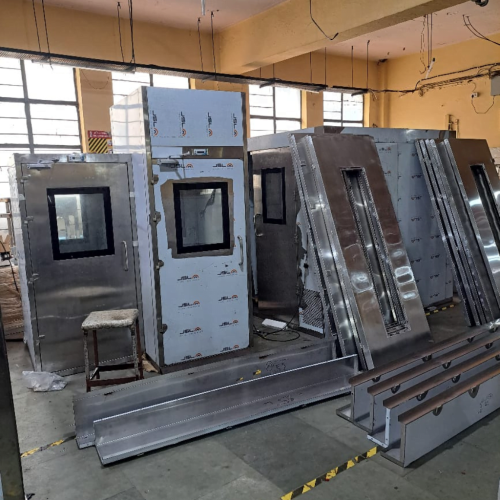

Recent PROJECTS

Why CRONAX?

7,00,000+ Trusted Customers

Certified Products

LifeTime Customer Support

Global Presence

Pan India Free Delivery

Why CRONAX?

7,00,000+ Trusted Customers

450+ Team Size

24/7 Customer Support

Certified Products

Global Presence

Pan India Free Delivery

Our CLIENTELE

Feel free to connect with our team of Experts to discuss your requirement!

ENTRANCE AUTOMATION

- High Speed Doors

- Sectional Overhead Doors

- Motorised Rolling Shutters

- Loading Bay Equipment

- Automatic Sliding Doors

- Entrance Doors

Pan india presence

- Bangalore

- Mumbai

- Chennai

- Hyderabad

- Kolkata

- Pune

- Delhi

- Gujarat

- Ahmedabad

- Faridabad

- Gurugram

- Noida

- Amritsar

GLOBAL PRESENCE

- Dubai (UAE)

- USA

- Nepal

- Bali

- Bangladesh

- South Africa

- Sri Lanka

EXPLORE

- Cronax Certificates

- Blog Articles

- Enquiry

- FAQ's

- Complaint Registration

BROCHURE

Pan india presence

- Bangalore

- Mumbai

- Chennai

- Hyderabad

- Kolkata

- Pune

- Delhi

- Gujarat

- Ahmedabad

- Faridabad

- Gurugram

- Noida

- Amritsar

GLOBAL PRESENCE

- Dubai (UAE)

- USA

- Nepal

- Bangladesh

- South Africa

© 2013-2024 Copyright Cronax Industries – All Rights Reserved.