Air Shower Manufacturers in Mumbai

At Cronax Industries, we are leading air shower manufacturers in Pune, providing advanced solutions to meet the cleanliness and hygiene needs of various industries. Our air showers are engineered to enhance operational efficiency by removing dust, contaminants, and particles from personnel before they enter controlled environments.

Our air showers are ideal for a wide range of applications, including pharmaceuticals, electronics, food processing, and cleanroom environments. Designed with high-velocity air jets and state-of-the-art filtration systems, our products ensure superior performance and reliability.

In Pune’s dynamic industrial landscape, our air showers help maintain stringent hygiene standards, reduce maintenance costs, and improve overall cleanliness. Whether you need a customized solution for a high-traffic area or a standard unit for specific applications, Cronax Industries delivers top-quality products that meet your exact requirements.

What Is An Air Shower?

Air showers are specialized enclosed chambers typically used in cleanroom environments or controlled environments. They serve as a critical contamination control measure, preventing particles from entering a clean area. Here’s a brief overview:

Air showers use high-velocity, HEPA-filtered air jets to remove dust, particles, and other contaminants from personnel or equipment before they enter a cleanroom.

These chambers are usually designed with interlocking doors to ensure that both doors are not open at the same time, maintaining the cleanroom’s integrity.

When a person or object enters the air shower, the doors lock, and a series of air jets are activated. The high-speed air jets dislodge and blow off contaminants, which are then captured by the air shower’s filtration system.

Commonly used in industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, and food processing, where maintaining a contaminant-free environment is critical.

Importance of Air Shower in Cleanrooms

Air showers are critical in maintaining the integrity of cleanrooms by ensuring that contaminants are minimized. An air shower system clean room setup ensures that the highest levels of cleanliness are maintained, which is crucial for industries such as pharmaceuticals, biotechnology, and semiconductor manufacturing.

The Working of an Air Shower

The working of an air shower involves several steps to effectively remove contaminants from personnel or equipment before they enter a cleanroom or controlled environment. Here’s a detailed explanation of how an air shower chamber works:

1. Entry and Activation:

- Access: The person or object enters the air shower through an entry door, which is usually interlocked with the exit door to prevent both from being open simultaneously.

- Detection: Sensors detect the presence of the person or object, automatically activating the air shower cycle.

2. High-Velocity Air Jets:

- Air Jets Activation: High-velocity jets of HEPA-filtered air are directed at the person or object from multiple nozzles positioned inside the chamber.

- Airflow: The air jets create a turbulent flow that dislodges and blows off particulate matter, dust, and other contaminants from the surfaces.

3. Contaminant Removal:

- Filtration System: The dislodged contaminants are captured by the air shower’s filtration system. The air is recirculated through HEPA (High-Efficiency Particulate Air) filters that remove 99.97% of particles as small as 0.3 microns.

- Air Circulation: Clean, filtered air is continuously circulated within the chamber to maintain an effective cleaning process.

4. Cycle Completion:

- Cycle Duration: The air shower cycle typically lasts between 20 to 60 seconds, depending on the design and requirements of the cleanroom.

- Deactivation: Once the cycle is complete, the air jets stop, and the exit door unlocks.

5. Exit and Access to Cleanroom:

- Exiting: The person or object exits the air shower booth through the exit door, now free of contaminants.

- Entry to Cleanroom: They can now enter the cleanroom or controlled environment with significantly reduced risk of introducing contaminants.

Key Components of an Air Shower:

- Interlocking Doors: Prevent both entry and exit doors from being open at the same time to maintain cleanroom integrity.

- HEPA Filters: Capture and remove particulate contaminants from the air.

- High-Velocity Air Nozzles: Direct jets of clean air to dislodge contaminants.

- Control System: Manages the operation of the air shower, including timing, air jet activation, and door interlocking.

Contact Us

Cronax – Pune’s Largest Air Showers Original Equipment Manufacturer (OEM)

1. Construction and Design:

- Material: Stainless steel (304/316), powder-coated steel, or other durable materials.

- Dimensions:

- External: (customizable based on requirements)

- Internal: (customizable based on requirements)

- Doors:

- Type: Interlocking, manual, or automatic sliding/swing doors.

- Material: Stainless steel, tempered glass.

- Operation: Pneumatic or electric control.

2. Airflow and Filtration:

- Air Velocity: 20-25 m/s (meters per second) at nozzle exit.

- Airflow Volume:

- Supply: 1000-2000 CFM (cubic feet per minute) depending on size and model.

- Exhaust: Matching supply volume to ensure balanced pressure.

- Filtration:

- Pre-filters: G4 (EN779) or MERV 10-13.

- HEPA filters: H13/H14 (EN1822) or equivalent, with 99.97% efficiency at 0.3 microns.

3. Air Shower Room Cycle:

- Cycle Time: Adjustable, typically 15-60 seconds.

- Air Jets:

- Number: 10-30 adjustable nozzles (varies based on model and size).

- Configuration: Multi-directional, strategically placed for optimal coverage.

- Noise Level: Below 70 dB(A).

4. Control System:

- User Interface: Touchscreen control panel or PLC-based system.

- Control Features:

- Cycle start/stop.

- Adjustable cycle time.

- Door interlock status.

- Filter status indicators.

- Interlock System: Ensures one door remains closed while the other is open to maintain cleanroom integrity.

5. Electrical and Power:

- Power Supply: 220-240V, 50/60 Hz, single-phase or three-phase.

- Power Consumption: 1-2 kW (varies based on model and features).

- Emergency Stop: Accessible emergency stop button.

6. Safety Features:

- Emergency Interlock Release: Allows manual override of door interlock in case of emergency.

- Alarm System: Visual and audible alarms for system faults, door status, and emergency conditions.

- Door Sensors: Proximity or magnetic sensors to detect door status.

7. Compliance and Standards:

- Cleanroom Standards: ISO 14644-1, ISO 14698.

- Electrical Safety: CE, UL, or equivalent certifications.

- Air Quality Standards: Compliance with industry-specific air cleanliness standards.

8. Optional Features:

- UV-C Sterilization: For additional microbial decontamination.

- Ionization System: For enhanced particle removal.

- Custom Size and Design: Tailored to specific application needs.

- Remote Monitoring and Control: Integration with building management systems (BMS).

Cronax Industries: Pune’s Largest Air Shower Original Equipment Manufacturer (OEM)

The Key Benefits of Air Showers

n Pune, a city characterized by its diverse climate and growing industrial base, air showers are becoming an increasingly vital component in maintaining cleanliness and efficiency in various settings. This article explores the benefits of air showers in Pune, considering the city’s specific environmental conditions and industrial needs.

1. Effective Dust and Pollution Control

Pune experiences significant levels of dust and air pollution, particularly during the dry season and in areas with high vehicular and industrial activity. Air showers play a crucial role in controlling these contaminants by removing dust, dirt, and particulate matter from personnel and materials before they enter clean or controlled environments.

- Prevention of Contamination: By dislodging and expelling dust and pollutants, air showers help prevent these contaminants from entering sensitive areas such as cleanrooms, laboratories, and manufacturing spaces.

- Improved Cleanliness: The result is a significant reduction in contamination levels, leading to cleaner production environments and better quality control.

2. Enhanced Hygiene Standards

Maintaining high hygiene standards is essential in Pune’s industrial and pharmaceutical sectors. The city’s varying weather conditions, which include seasonal dust and occasional pollution spikes, necessitate effective solutions for cleanliness.

- Thorough Cleaning: Air showers provide a robust method for removing contaminants from clothing and equipment, ensuring that individuals and materials entering sensitive areas are clean.

- Health and Safety: By reducing the presence of external contaminants, air showers contribute to a healthier and safer working environment, mitigating risks associated with contamination.

3. Energy Efficiency and Cost Savings

Pune’s moderate climate allows for efficient energy management, which is further enhanced by the use of air showers.

- Reduced HVAC Load: By minimizing the amount of dust and contaminants entering climate-controlled spaces, air showers help reduce the workload on HVAC systems. This leads to lower energy consumption and operational costs.

- Cost Efficiency: The reduced need for intensive climate control translates to significant cost savings over time, making air showers a cost-effective solution for maintaining optimal conditions.

4. Lower Maintenance Costs

Maintaining cleanliness and operational efficiency in Pune’s dust-prone environment can be challenging and costly. Air showers help alleviate some of these challenges by reducing the frequency and intensity of maintenance required.

- Less Frequent Cleaning: With fewer contaminants entering clean areas, the need for extensive cleaning and maintenance is diminished. This reduces both direct cleaning costs and the wear and tear on equipment.

- Long-Term Savings: The overall reduction in maintenance activities and associated costs contributes to significant long-term savings for businesses and facilities.

5. Enhanced Workplace Safety

Workplace safety is a critical concern in Pune, particularly in sectors such as pharmaceuticals, electronics, and manufacturing. Air showers contribute to a safer working environment by ensuring that contaminants are removed before entering controlled areas.

- Compliance and Safety: By adhering to strict cleanliness standards, air showers help facilities comply with industry regulations and safety protocols, reducing the risk of contamination-related incidents.

- Improved Work Conditions: A cleaner environment enhances overall workplace safety, reducing the likelihood of contamination-related accidents and ensuring a healthier workspace for employees.

6. Adaptability to Pune’s Climate

Pune’s climate, characterized by moderate temperatures and seasonal variations, complements the use of air showers.

- Efficient Performance: The city’s climate allows air showers to operate efficiently, maintaining consistent performance throughout the year without significant fluctuations in energy consumption.

- Integration with Existing Systems: Air showers can be seamlessly integrated into existing HVAC and cleanroom systems, adapting to the city’s diverse environmental conditions and enhancing overall operational efficiency.

7. Support for Industrial Growth

As Pune continues to grow as an industrial and technological hub, air showers support this growth by providing essential contamination control solutions.

- Scalability: Air showers can be scaled and customized to meet the needs of expanding industries and evolving technological requirements.

- Innovation and Development: Leading manufacturers in Pune, such as Cronax Industries, offer advanced air shower systems that support innovation and development in various sectors, contributing to the city’s industrial advancement.

Cronax Industries: Pune’s Largest Air Shower Original Equipment Manufacturer (OEM)

In Pune, air showers find extensive application across various industries and facilities, contributing to enhanced cleanliness, safety, and operational efficiency. Here’s an overview of their key applications in the city:

1. Pharmaceutical Industry

- Cleanroom Maintenance: Air showers are essential in pharmaceutical manufacturing and research labs to maintain the stringent cleanliness required for drug production and research. They help ensure that personnel and materials entering cleanrooms are free from contaminants.

- Compliance with Regulations: They assist in meeting regulatory requirements for contamination control, crucial for maintaining product quality and safety in the pharmaceutical sector.

2. Electronics and Semiconductor Manufacturing

- Contamination Control: In electronics and semiconductor facilities, air showers prevent dust and other particulates from contaminating sensitive electronic components and production areas. This is critical for maintaining high-quality standards and avoiding defects.

- Enhanced Production Efficiency: By reducing contamination risks, air showers help improve the efficiency and reliability of electronic manufacturing processes.

3. Food and Beverage Industry

- Hygiene Assurance: In food processing and packaging plants, air showers are used to ensure that employees and materials entering production areas are free from contaminants, thereby maintaining hygiene and food safety standards.

- Prevention of Cross-Contamination: Air showers help prevent cross-contamination between different stages of food processing, which is vital for maintaining product quality and safety.

4. Biotechnology and Life Sciences

- Sterile Environment Maintenance: Air showers are employed in biotechnology and life sciences labs to ensure that personnel and equipment are clean before entering sterile environments. This is crucial for preventing contamination of research samples and experiments.

- Support for Research and Development: By maintaining clean conditions, air showers support the integrity of research and development processes in biotech and life sciences fields.

5. Hospitals and Healthcare Facilities

- Infection Control: In hospitals and healthcare facilities, air showers help control infection by removing contaminants from staff and equipment before they enter critical areas such as operating rooms and intensive care units.

- Enhanced Patient Safety: By contributing to a cleaner environment, air showers play a role in improving overall patient safety and reducing the risk of hospital-acquired infections.

6. Automotive Manufacturing

- Contamination Prevention: In automotive manufacturing plants, air showers are used to keep assembly lines and production areas free from dust and other contaminants, ensuring high-quality finishes and optimal performance of automotive components.

- Quality Control: They contribute to the maintenance of high-quality standards and operational efficiency in automotive production processes.

7. Research Laboratories

- Maintaining Clean Conditions: Air showers are used in research laboratories to ensure that researchers and equipment entering sensitive experimental areas are free from contaminants. This is essential for obtaining accurate and reliable results.

- Supporting Scientific Innovation: By providing a clean environment, air showers support scientific research and innovation in various fields.

8. Manufacturing Facilities

- Operational Efficiency: In general manufacturing facilities, air showers help maintain clean conditions by reducing the entry of dust and debris, which is crucial for smooth operations and reducing downtime due to contamination issues.

- Cost Savings: They help lower maintenance and cleaning costs by minimizing the introduction of contaminants into production areas.

Cronax Industries: Pune's Largest Air Shower Original Equipment Manufacturer (OEM)

Cronax Air Showers,featuring HEPA filtration, adjustable air velocity, customizable sizes, with a 3-year warranty.

1. What is an air shower?

An air shower is an enclosed chamber that uses high-velocity, HEPA-filtered air jets to remove dust, particles, and other contaminants from personnel or equipment before they enter a cleanroom or controlled environment.

2. How does an air shower work?

An air shower works by directing high-velocity air jets at the person or object entering the chamber. These air jets dislodge and blow off contaminants, which are then captured by the chamber’s filtration system. The air is recirculated through HEPA filters to ensure only clean air is used.

3. Why do I need an air shower? Air showers are essential for maintaining contamination control in cleanrooms and other controlled environments. They help prevent contaminants from entering critical areas, thereby ensuring product quality, safety, and compliance with regulatory standards.

4. Where are air showers typically used?

Air showers are commonly used in industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, food processing, aerospace, defense, healthcare, laboratories, and more. Industrial air showers ensure contamination control by decontaminating personnel and equipment entering sensitive environments like manufacturing facilities.

5. How much space is required to install an air shower?

The space required depends on the size and design of the air shower. Air showers come in various sizes, so it’s important to measure the available space and consult with the manufacturer to determine the appropriate model for your needs.

6. How long does an air shower cycle take?

The duration of an air shower cycle is typically adjustable, ranging from 15 to 60 seconds. The exact time can be set based on the specific requirements of your application.

7. Can the air shower be customized to fit our needs?

Yes, air showers can be customized in terms of size, material, and features to meet the specific requirements of your facility and application.

8. What kind of maintenance is required for an air shower?

Regular maintenance includes cleaning or replacing pre-filters and HEPA filters, checking the operation of air jets, and ensuring that the control systems and door interlocks are functioning correctly. It’s recommended to follow the manufacturer’s maintenance guidelines.

9. How noisy is an air shower?

The noise level of an air shower is generally below 70 dB(A), which is comparable to the sound of a normal conversation.

10. What power supply is needed for an air shower?

Air showers typically require a power supply of 220-240V, 50/60 Hz, single-phase or three-phase, depending on the model.

11. What safety features are included in an air shower?

Safety features of air showers include interlocking doors to prevent both doors from being open simultaneously, emergency stop buttons, visual and audible alarms for system faults, and emergency interlock release mechanisms.

12. Are there different types of air showers?

Air showers come in various configurations, including single-person, multiple-person, tunnel, and equipment-specific designs, to suit different applications and facility layouts.

13. What is the cost of an air shower?

The cost of an air shower varies based on the size, features, and customization options. It’s best to request a quote from the manufacturer based on your specific needs.

14. How can I determine the right air shower for my facility?

To determine the right air shower, consider factors such as the size of the area, the number of personnel or amount of equipment needing decontamination, and specific cleanliness standards. Consulting with a manufacturer or cleanroom expert can help you choose the best option.

15. Top Air Shower Manufacturers in India?

There are several air shower manufacturers around the world who provide customized solutions to meet specific industry needs. Cronax Industires is one of the best air shower manufacturers in India offering a range of products tailored to local requirements and compliance standards.

16. What factors affect the air shower clean room price?

The price of an air shower for a clean room can vary based on several factors, including the size and configuration of the unit, the type of filtration system used (such as HEPA or ULPA filters), additional features like interlocking doors or programmable controls, and the materials used in construction (stainless steel, powder-coated steel, etc.). Customization options, installation costs, and the manufacturer’s brand and reputation also play a significant role in determining the overall cost.

17. Air Shower Price at Cronax Industries?

At Cronax Industries, air shower prices are determined based on several factors, particularly the customization of the product to meet specific customer requirements. Customization options such as size, material, filtration system (HEPA or ULPA), additional features (such as interlocking doors or programmable controls), and installation requirements all influence the final pricing. Buy air shower today with Cronax Industries.

18. What is a Pass Box air shower?

A pass box air shower typically refers to a specialized unit that combines the features of both a pass box and an air shower. It serves as a transfer chamber where materials or items can be passed between two environments (such as a clean room and an external area) while decontaminating through an air shower process.

19. What factors affect the cost of an air shower in Pune?

The cost of an air shower in Pune depends on factors such as the type of air shower, size, customization requirements, and additional features. Contact local suppliers to get a detailed quote based on your specific needs and preferences.

20. How can an air shower in Pune improve workplace safety?

An air shower in Pune enhances workplace safety by removing contaminants from personnel and equipment before they enter sensitive areas. This helps prevent contamination-related incidents and ensures a cleaner, safer working environment.

For a comprehensive understanding of our Air Shower's technical specifications, please download our catalogue.

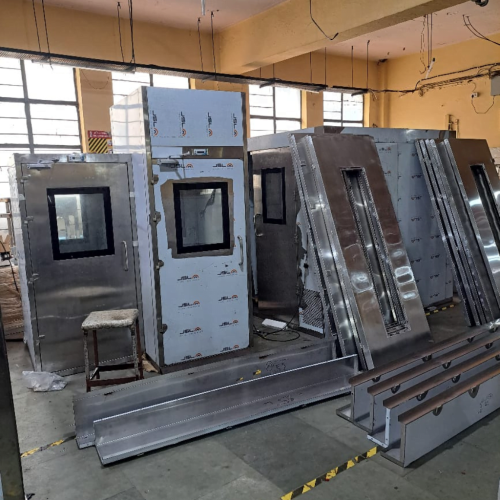

Recent PROJECTS

Why CRONAX?

7,00,000+ Trusted Customers

Certified Products

LifeTime Customer Support

Global Presence

Pan India Free Delivery

Why CRONAX?

7,00,000+ Trusted Customers

450+ Team Size

24/7 Customer Support

Certified Products

Global Presence

Pan India Free Delivery

Our CLIENTELE

Feel free to connect with our team of Experts to discuss your requirement!

ENTRANCE AUTOMATION

- High Speed Doors

- Sectional Overhead Doors

- Motorised Rolling Shutters

- Loading Bay Equipment

- Automatic Sliding Doors

- Entrance Doors

Pan india presence

- Bangalore

- Mumbai

- Chennai

- Hyderabad

- Kolkata

- Pune

- Delhi

- Gujarat

- Ahmedabad

- Faridabad

- Gurugram

- Noida

- Amritsar

GLOBAL PRESENCE

- Dubai (UAE)

- USA

- Nepal

- Bali

- Bangladesh

- South Africa

- Sri Lanka

EXPLORE

- Cronax Certificates

- Blog Articles

- Enquiry

- FAQ's

- Complaint Registration

BROCHURE

Pan india presence

- Bangalore

- Mumbai

- Chennai

- Hyderabad

- Kolkata

- Pune

- Delhi

- Gujarat

- Ahmedabad

- Faridabad

- Gurugram

- Noida

- Amritsar

GLOBAL PRESENCE

- Dubai (UAE)

- USA

- Nepal

- Bangladesh

- South Africa

© 2013-2024 Copyright Cronax Industries – All Rights Reserved.